Background

This project aims to optimize and fabricate microwave circuitry for two-tone spectroscopy measurements of novel superconducting Josephson junctions. These junctions are distinctive, consisting of superconductor-semiconductor-superconductor structures based on planar strained Germanium, which exhibit a highly anisotropic spin-orbit interaction. When brought into contact with a superconductor to form a Josephson junction, these materials create “Andreev Bound States (ABS)”, which we are studying. ABS in these specialized semiconductor quantum wells lead to intriguing current-phase relations, which can be controlled using a top gate. By manipulating these, we can tailor the junction’s behavior, potentially utilizing them for superconducting qubits in the future. The project primarily focuses on developing and constructing the basis of the microwave readout circuitry. We will employ coplanar waveguide (CPW) feedlines and resonators, coupling them strongly with the system containing the bound states.

Superconducting resonators will be used to identify these bound states through spectroscopic measurements in the 3-10 GHz range. To create magnetic field-compatible CPW and lumped element resonators, we require superconducting films with low sheet resistance and a high critical field. All fabrication work will be carried out at the Helmholtz Nano Facility (HNF) in Forschungszentrum Jülich, using a specialized thin-film deposition tool in their ISO1 cleanroom, which is fully equipped for the fabrication and characterization of nanoscale devices.

Your Task

You will be using our thin film deposition tool to optimize NbTiN superconducting films to obtain the best temperature and field performance needed for obtaining high contrast two tone spectroscopy measurements for our Josephson junctions. You will be operating the tool independently to make superconducting thin films suited for the multitudes of our processes. You will gain cleanroom training and will be handling the fabrication line for resonators. Workplace for this part of the project will be Forschungszentrum Jülich.

Apart from the fabrication, the project will involve doing cryogenic temperature dependent four-point sheet resistance, X ray diffraction measurements and high frequency network analysis with the responsible PhD student. The later part of the project will consist of a full workup of the fabricated resonators in our Adiabatic Demagnetization Refrigerator and our Dilution Refrigerator equipped with a 9-1-1 T vector magnet in Aachen. We will be doing magnetic field sweeps to characterize multiple designs in different possible field configurations.

For a more measurement focussed project please look into the ADR project

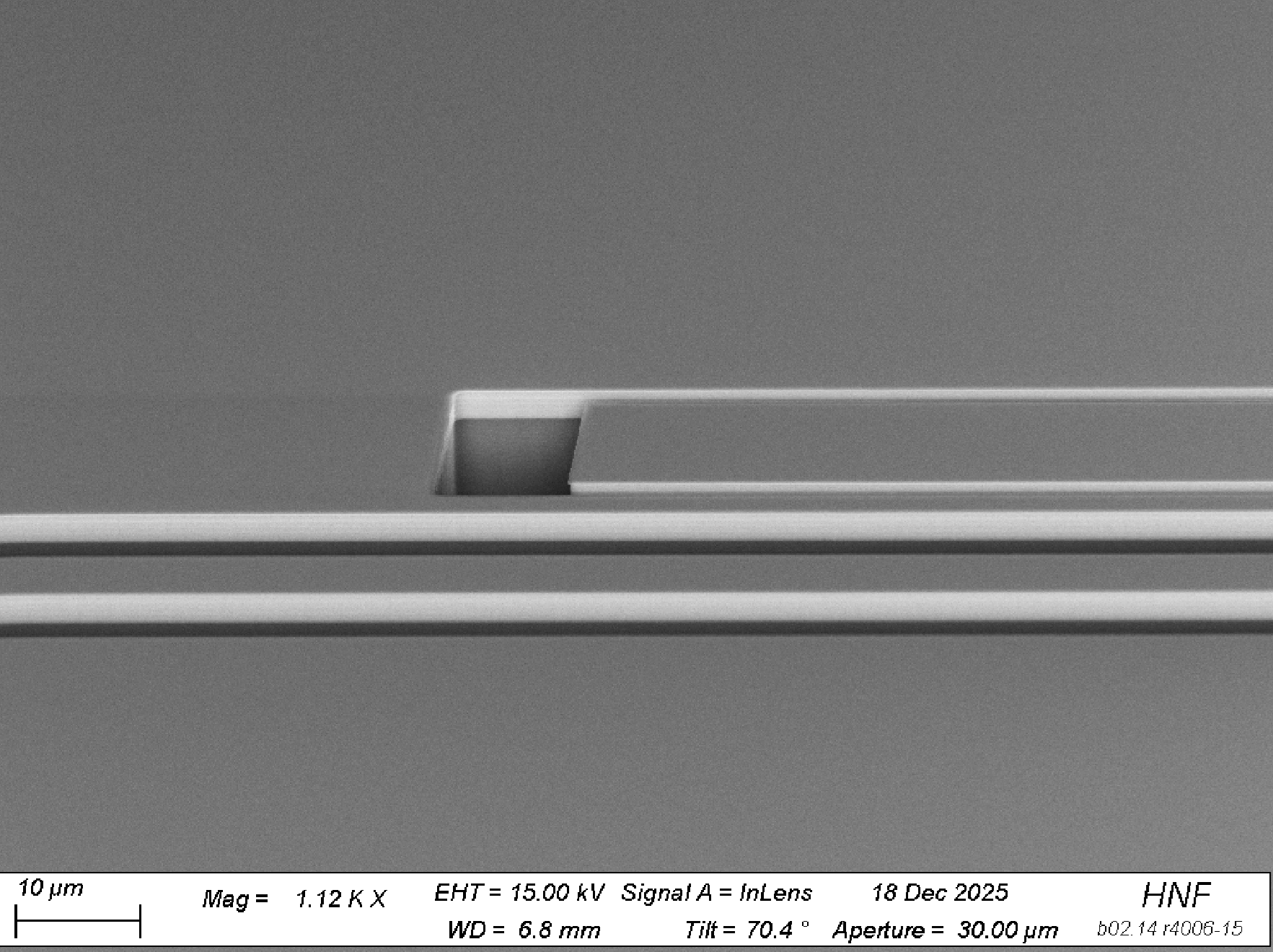

This scanning electron microscope (SEM) image shows parts of a NbTiN resonator. Here, the NbTiN as well as the substrate below have been etched down.

This scanning electron microscope (SEM) image shows parts of a NbTiN resonator. Here, the NbTiN as well as the substrate below have been etched down.

What we offer

- Workplace, laptop for duration of the project.

- An equivalent student assistant contract via Forschungszentrum Jülich

- Young, international, dynamical workplace, located on Campus Melaten (Campus Boulevard 79)

- Exposure to leading research activities in quantum technology

Supervision

- Dr. Vincent Mourik, FZ Jülich, PGI-11 [email protected]

- Spandan Anupam, FZ Jülich, PGI-11 [email protected]